The Future of CNC Machining: Trends Shaping Modern Manufacturing

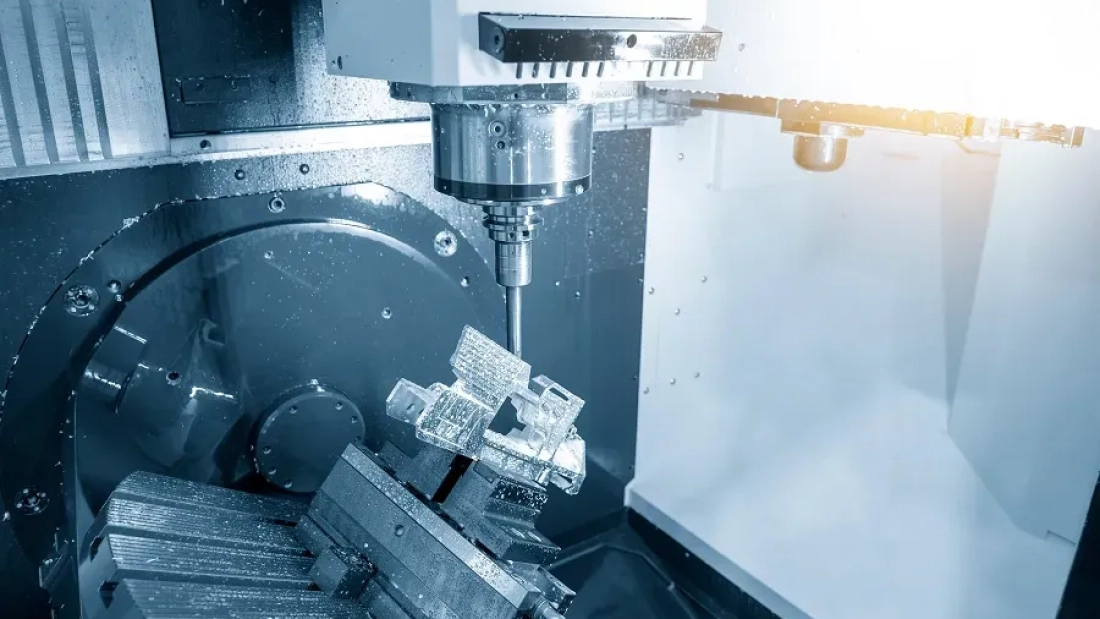

Introduction CNC machining has revolutionized the world of manufacturing. As industries evolve, so do the technologies that support them. The future of CNC machining is filled with innovation, increased precision, and automation. In this blog, we explore the latest trends that are shaping the future of CNC machining.

1. Integration of Artificial Intelligence (AI) AI is optimizing machine efficiency by predicting maintenance, reducing downtime, and enhancing quality control. Smart CNC machines can learn and adapt, making processes faster and more reliable.

2. Use of Advanced Materials With the growing demand for lightweight and durable components, CNC machines are now used to cut composites, ceramics, and specialized alloys. This pushes the boundary of what’s possible in precision engineering.

3. Automation and Smart Factories CNC machines are now part of fully automated manufacturing lines. Robotics and IoT devices are enhancing communication between machines, leading to seamless production processes.

4. Hybrid Manufacturing Combining CNC machining with additive manufacturing (3D printing) allows manufacturers to create complex parts with reduced waste and cost.

Conclusion The future of CNC machining is not just faster production — it’s smarter, more sustainable, and incredibly precise. Businesses embracing these trends will lead the next wave of manufacturing excellence.