From Concept to Creation: How Prototyping Accelerates Product Development

Introduction Prototyping is the bridge between an idea and a market-ready product. It enables businesses to test, validate, and refine their designs faster and more cost-effectively.

1. Types of Prototyping

- Visual models

- Functional prototypes

- 3D printed samples

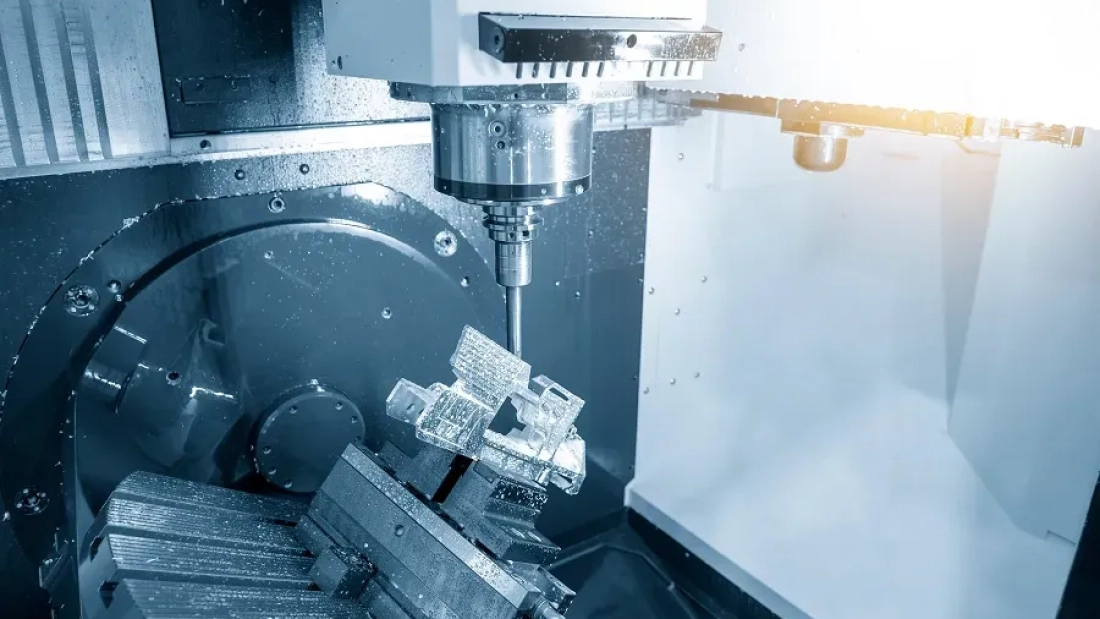

- CNC-machined samples

2. Benefits of Prototyping

- Detect design flaws early

- Improve user feedback and UX

- Save time and resources during mass production

3. Industry Applications From automotive and aerospace to consumer electronics and medical devices, prototyping is used to bring innovation to life.

Conclusion Prototyping isn’t an optional step—it’s an essential phase that enhances innovation, reduces risk, and ensures product success in competitive markets.